SOLVENT DYES

Solvent Red 24

1. Product Overview

Solvent Red 24 is a premium-grade synthetic azo dye known for its superior solubility in organic solvents and vibrant red color. With extensive applications in fuel coloring, plastics, printing inks, and leather dyeing, this dye offers exceptional performance and reliability, making it a top choice for industrial users.

2. Key Features

Bright Red Hue: Consistent, vibrant color for various applications.

High Solubility: Excellent performance in ethanol, benzene, and toluene.

Heat Resistance: Suitable for high-temperature industrial processes.

Versatility: Widely applicable in multiple industries, including fuels, polymers, and coatings.

UV Stability: Maintains color integrity under prolonged UV exposure.

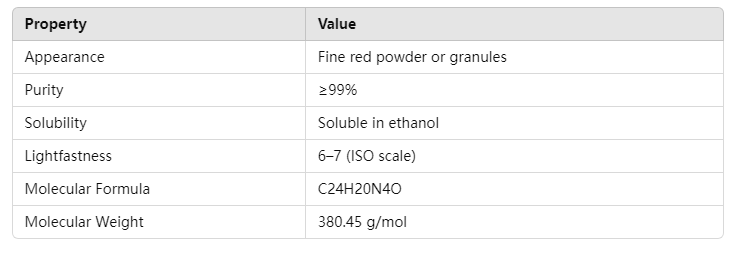

3. Technical Specifications

4. Applications

4.1 Fuel and Lubricant Dyeing

Used for identifying and branding gasoline, diesel, and other fuels.

Enhances product differentiation with vivid red coloration.

4.2 Plastic and Polymer Coloring

Ideal for coloring plastics like PVC, polystyrene, and polyolefins.

Ensures long-lasting, heat-stable coloration during processing.

4.3 Printing Inks and Coatings

Utilized in solvent-based printing inks for vibrant, durable prints.

Perfect for varnishes, lacquers, and other high-performance coatings.

4.4 Leather Finishing

Widely used for leather dyeing, providing uniform and rich color for high-quality finishes.

5. Production Process

5.1 Raw Materials

Aniline: The core raw material for diazotization.

Naphthol: Essential for forming the azo bond.

Sulfuric Acid: Catalyst for the chemical reaction.

Solvent Medium: Ensures optimal solubility of the final product.

5.2 Manufacturing Steps

Diazotization: Aniline is diazotized with sodium nitrite and hydrochloric acid.

Coupling Reaction: The diazo compound reacts with naphthol to form the dye.

Purification: Crude dye is filtered, washed, and dried to achieve high purity.

Final Formulation: Solvent blending ensures excellent solubility and consistent quality.

6. Packaging and Storage

Packaging Options:

25 kg kraft paper bags

25 kg iron drums

Customizable packaging available for bulk orders

Storage Conditions:

Store in a cool, dry environment away from sunlight and moisture to maintain product integrity.Shelf Life:

Up to 24 months under proper storage conditions.

7. Safety Guidelines

Avoid inhaling dust or allowing direct skin contact.

Wear protective gear such as gloves, goggles, and masks while handling.

Refer to the comprehensive Material Safety Data Sheet (MSDS) for safe usage instructions.

8. Why Choose Solvent Red 24 from Tianjin Uniwin?

Unmatched Quality: Every batch undergoes rigorous testing to meet international standards.

Competitive Pricing: High-quality dyes at cost-effective rates.

Global Supply Chain: Reliable delivery to customers worldwide.

With Tianjin Uniwin, you get a trusted partner for all your industrial dye needs. Contact us today to request a quote or sample for Solvent Red 24.

CATEGORIES

BLOGS

- The Future of the Dye Industry: How Automated Dye Dispensing Systems Are Changing the Game

- Eco-Friendly Sulphur Dyes: The Future of Sustainable Textile Manufacturing

- Achieving Carbon Neutrality in the Textile Industry with Tianjin Uniwin’s Sustainable Dye Solutions

- Revolutionizing the Textile Industry with Waterless Dyeing Technology

- Revolutionizing the Textile Industry: The Growing Market for Recycled Textiles

CONTACT US

Tel: 8613642040418

Email:info@tjuniwin.com

Add: Liutangzhuang , Zhongtang , Dagang, Binhai District, Tianjin, China